As featured on https://www.linkedin.com/pulse/radical-reinvention-sustainability-indonesian-style-ubs-gwm by UBS Global Wealth Management.

Haryanto Tjiptodihardjo, president-director of the Indonesian building-material manufacturer, PT Impack Pratama Industri, is talking about the bad old days in 1997, when the Asian crisis was raging and his family firm was in serious trouble. Then a maker of consumer packaging, Impack had to buy its expensive raw material from the take-it-or-leave-it global petrochemical giants, before selling its finished packaging goods to equally unforgiving customers in the global consumer industry. Both supplier and customer were relentlessly squeezing the Indonesia manufacturer on price.

“The customers were very nice,” he says with a dry smile. They “wanted to give us this big order, but warned it was steamed white rice, no meat, and wouldn’t taste good. But we could survive.”

It was unsustainable. That same year Haryanto’s father appointed his middle son the company’s chief executive and instructed him to rescue their family business. Haryanto did so by orchestrating a radical corporate transformation, away from low-margin consumer packaging towards the more profitable business of building materials.

Turning Impack into a sustainable business

It was a logical move. Both businesses relied on Impack’s know-how in making durable products out of plastic polymers, and the company today sells everything from corrugated polycarbonate sheet used in roofing to piping and gutters made from PVC. The problem: While Impack’s products are helpful to the people of Indonesia – they allow families to build durable homes at relatively low cost – many are also harmful to the environment.

In time, as Haryanto aged and his son came up, this harsh environmental reality began to grate on Haryanto, partly because he believes in a Higher Being. His fortune, he says gently during our interview, is “by God’s grace, all glory back to him.” So, four years ago, wanting to do better and be better, Haryanto initiated another radical transformation at his company.

This time around Haryanto is turning Impack into a sustainable business, a showcase for other Asian firms to possibly emulate, as we head deeper into the turmoil of the 21st Century.

“We want to prove the people wrong,” Haryanto says. “There are ways that companies can do well – and at the same time do good things.”

Impack’s radical reinvention started unassumingly in 2017 when a Bayer spin-off, Covestro, asked Impack if it wanted to partner with them in a new ‘inclusive’ business building a low-cost solar drying dome to serve Indonesia’s subsistence farmers. Covestro said the dome would make small farmers far more efficient and profitable drying everything from chili to cocoa. Why Impack? The drying dome was made from polycarbonate sheet that Impack was already making out of Covestro’s resin and using in its building-material business.

“Covestro said, ‘this tool will have a big impact on an underserved community but building the business will take a lot of effort and be very challenging. You need to educate the farmers, talk to the right people in government, and the logistics, delivering across Indonesia’s islands, will be a nightmare. You will face a wall. But the reward will come – later on.’”

In 2018, Haryanto started scaling the ‘wall,’ not just in Indonesia, but in Thailand, Laos, Cambodia, Malaysia and Myanmar, where his firm also has a presence. Four years later, Impack’s solar drying dome is sold in 30 of Indonesia’s 34 provinces, and roughly doubled the production and income of some 360,000 beneficiaries across Asia.

“… companies can do well – and at the same time do good ….”

In short, Haryanto and his family are doing their bit to collectively reach the UN’s Sustainable Development Goals, meant to lift the economic opportunities of the world’s disenfranchised in the least harmful way possible. Riswati Wahyuni of the Hattaki Farmers Group in West Java says that drying chilies traditionally took her seven to eight days; the Impack dome completes the drying process in three to five days, in effect doubling her production. The dried chilies, she explains, “are also more hygienic and there is little or no bacterial contamination, which has added value to my sales.”

Haryanto says this fast-growing business is still just 1% of his total revenue but it’s already profitable. More importantly, the dome fanned Haryanto’s imagination, and he has since worked tirelessly to integrate Sustainability goals into every facet of his business. He appointed a Sustainability Officer, started installing solar panels at his factories, and published transparent Sustainability targets and performance reviews that shareholders of the publicly traded Impack could easily track. Result: The Indonesian firm won the 2021 “Outstanding Best Practices” top honor granted by the Global Corporate Sustainability Award.

Imagine if 1% of the 18 billion metric tons of building materials was made from recycled material

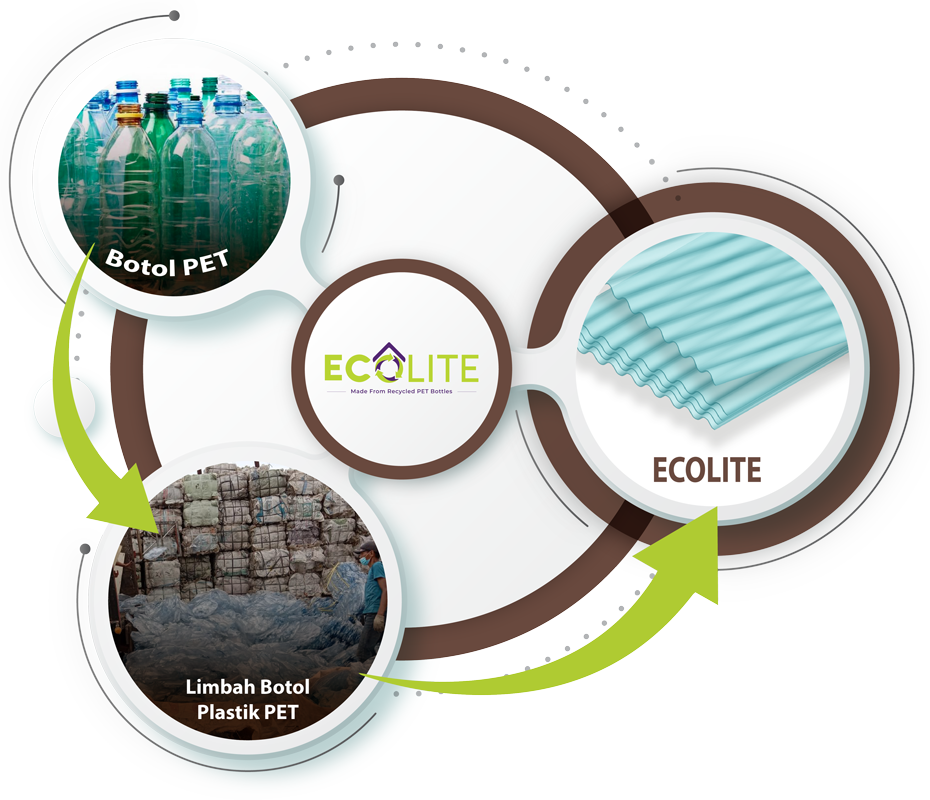

But Haryanto was still not content. The dome did ‘good’ by helping to lift farmers out of poverty and cutting over 500 metric tons of carbon dioxide from the atmosphere, but it was still made of polycarbonate sheet. Haryanto felt he and his firm had a particular responsibility to remove plastics from this earth, due to the nature of their business, so he challenged his lab to create new building-materials products from the massive waste piles of plastic bottles and bags that litter the world.

“I understand that in the whole world, there are around 18-billion metric tons of building materials— concrete, steel, metals, glass, plastics, and ceramics— used in making homes, office towers, and so on. Imagine if somehow in the future, 1% of those 18-billion metric tons was made from recycled material, corresponding to around 180-million metric tons of recycled plastic.”

Haryanto’s ‘just imagine’ talks inspired his employees and they rose to the challenge. Impack now turns discarded soft drink bottles into Ecolite, a low-cost shed-roofing that Indonesians use to shield their air-dried laundry from downpours. The neat feature here: Spent plastic bottles are currently collected by scavengers, recycled, ground up, and fed back into new plastic bottles as they are produced, which are promptly used by consumers and once again dumped into landfill. It’s an endless vicious circle. Ecolite roofing productively extends the plastic bottle’s life to some 7 or 8 years and takes them out of the waste piles.

There’s more. Discarded plastic bags are now being repurposed into a core layer of insulation within aluminum-composite panels, while used plastic cups are ground into pellets that produce colorful wall panels called Impraboard. Next up from the company’s inhouse lab: a board made from discarded multilayer packaging and mineral waste, which can potentially be used as picnic tables or toilet partitions.

Meanwhile, Germany’s Covestro, pleased with what Impack achieved with the dryer dome, has again entered negotiations with the Indonesian firm, this time to make solar-powered distillers that purify contaminated water, and a solar-run cooling storage unit meant to save the 35% of remote fishermen’s catches currently lost to spoilage.

What does all this mean? Impack estimates it is recycling more than 5,000 metric tons of plastic annually and that almost 12% of its products are now made from recycled waste.

Of course, these newly released Sustainable products account for just 4% or 5% of Impack’s total revenue, but as more such product innovations emerge, as consumers are educated and their trust in Impack’s low-cost environmental-friendly products gain traction, the financial reward for this industrial ‘reimagining’ should materially begin flowing to the bottom line.

“I think in 2024 the new businesses will start to kick in – in a big way,” Haryanto says.