SOLARTUFF VIDEO INSTALLATION GUIDE

SOLARTUFF GRECA

SOLARTUFF SOLID

SOLARTUFF CUSTOM GLAZE

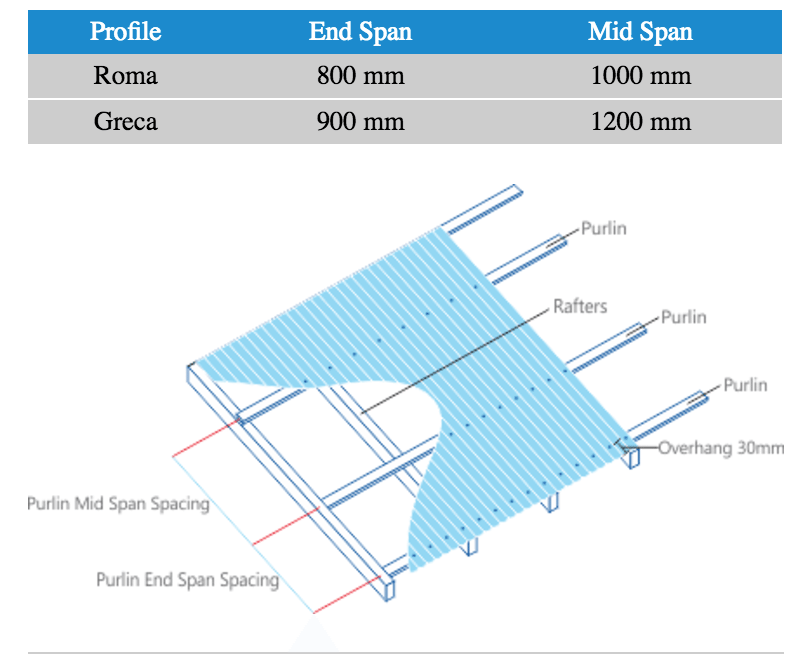

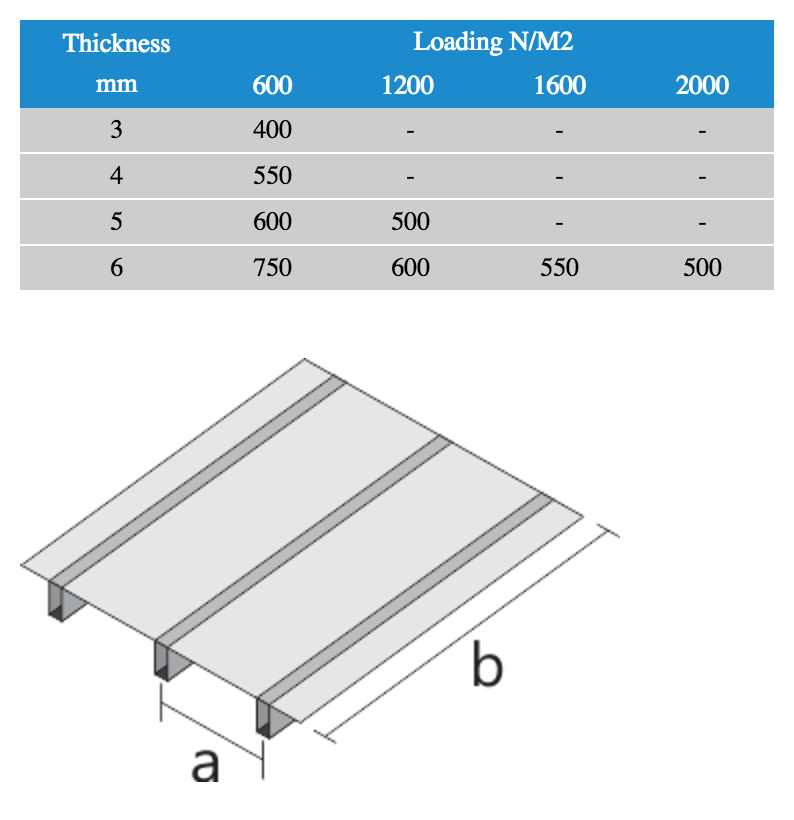

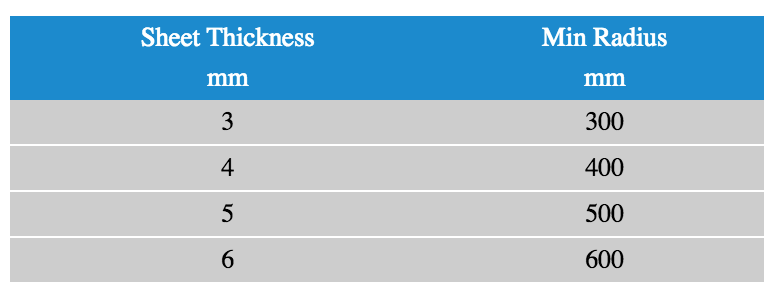

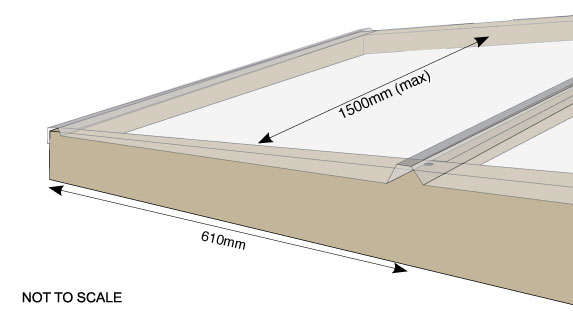

02 JARAK RANGKA

Rangka vertikal : 610 mm

Overhang : 100 mm

Rangka horizontal :

1,500 mm (area bertekanan angin rendah)

600 mm (area bertekanan angin tinggi)

03 PEREDAM BISING

Area dengan tekanan angin tinggi dapat menyebabkan bising pada lembaran produk. Gunakan plaster peredam bising berwarna putih.

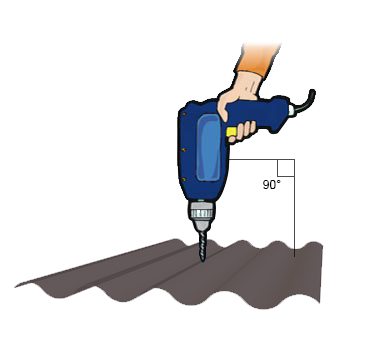

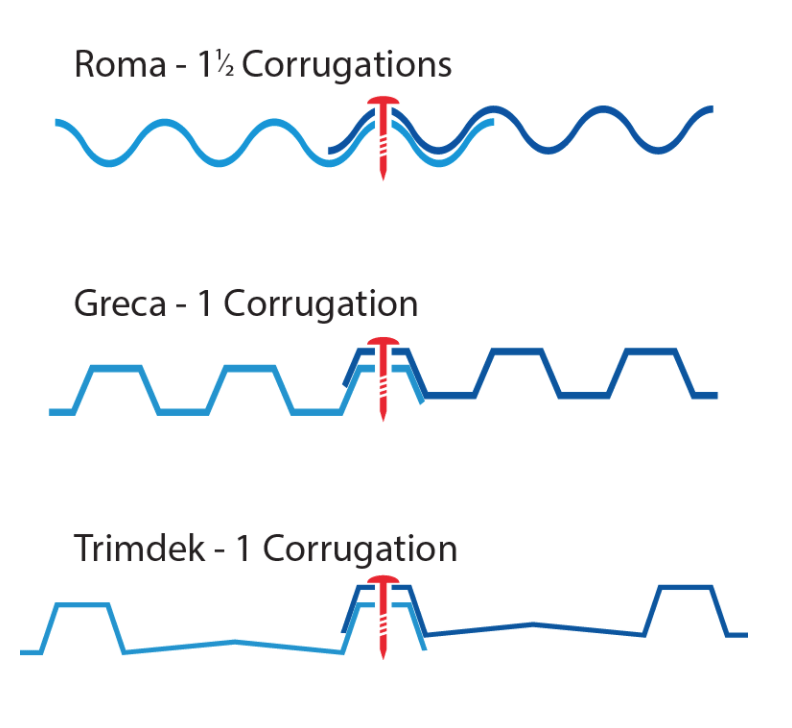

04 PEMASANGAN SEKRUP

Produk berekspansi di bawah panas matahari. Berikan ruang ekspansi dengan melakukan bor pendahuluan pada produk menggunakan mata bor berdiameter 2-3 mm lebih besar dari diameter batang sekrup. Pasang sekrup dengan obeng elektrik. Jangan memasang sekrup miring atau melesak. Gunakan sekrup berkepala datar dengan karet EPDM.

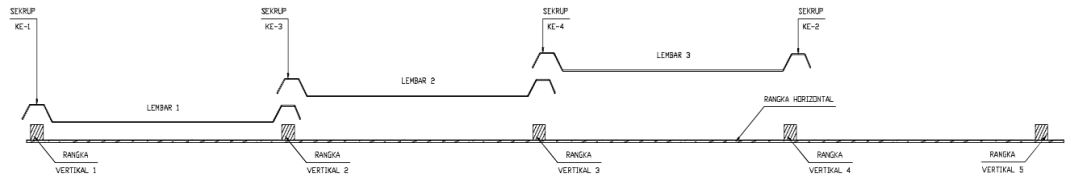

05 PENYAMBUNGAN SAMPING

Puncak atas Custom Glaze lebih lebar dan lebih tinggi daripada puncak bawah, juga ditandai dengan cetakan tinta bertuliskan : “CG610/OVERLAPPING CREST”. Puncak atas diinstall di atas puncak bawah pada penyambungan samping.

Berikut cara pemasangannya:

- Selesaikan semua pekerjaan konstruksi lainnya sehingga lembaran produk bisa terpasang tanpa debu atau kotoran lain berterbangan yang dapat menyebabkan goresan pada produk.

- Lepaskan film pelindung bagian belakang.

- Letakkan lembar produk pertama (lembar 1) hingga puncak atasnya berada di titik tengah rangka vertikal. Pasang sekrup hanya di puncak atas, sepanjang rangka vertikal dengan jarak satu sekrup ke sekrup lainnya sebesar 500 mm.

- Letakkan lembar produk ketiga (lembar 3) di rangka vertikal ke-4. lalu pasang sekrup hanya di puncak bawah.

- Masukkan lembar produk kedua (lembar 2) di tengah-tengah antara lembar 1 dan lembar 3. Posisikan puncak atas lembar 2 berada di atas puncak bawah lembar 1. Juga puncak bawah lembar 2 berada di bawah puncak atas lembar 3. Lalu pasang sekrup.

- Lanjutkan pemasangan untuk 3 lembar produk berikutnya hingga seluruh rangka tertutup. Dengan cara ini, akan menjaga kestabilan bagian datar dari produk dan posisi puncak atas lebih akurat.

- Lepaskan film pelindung bagian depan jika instalasi produk telah selesai.

ANY FURTHER QUESTIONS?

For further information on our products, please simply fill in the form below and our representative will respond to you as soon as possible.